Brand Name: PEIDE Frequency conversion processing

Model Number: CLDC-CR Frequency conversion processing

Place of Origin: Jiangsu, China (Mainland)

Electronic induction type Frequency conversion processing water treatment

Frequency conversion processing Introduction

Digital induction water descaler especially used at high hardness water treating. Good reasons of stable operation, long-time efficiency, long-distance effective signal transfer, which widely used at oily water, chemical industry, electricity, metallurgical industry, textile, and waste water.

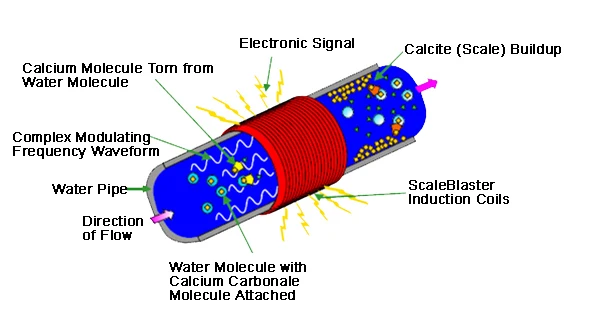

Prevent Scale: Electronic Induction water treatment equipment forms electromagnetic field which regularly changes frequency and intensity. The field makes carbonate ion forming quantity Aragonite. When mineral content exceed the saturation solubility, carbonate ion will form the Aragonite preferential. The tendency of forming Calcite will reduce. The adhesion of Aragonite is weak and Aragonite is soft, flocculent and suspend on the water. It is easy to remove by water flow to reaches to the purpose of preventing scale.

Cleaning Scale: The scale which is on the surface of pipe disassembles to carbonate ion. The carbonate will form the Aragonite instead of Calcite in AV function. What’s more, the scale will be off from pipe surface.

Kill bacterial: Scale is breeding ground of bacterial. If the scale is cleaned. That’s means, the breeding ground of bacterial is cleaned. What’s more, the electromagnetic field will damage the cell’s cytoderm to cause difficult to survive. The solubility ability and dissolve of oxygen will improve in water after treated to inhibit anaerobic bacterial survive.

Descaling and prevent corrosion: Water rust will be cleaned in electromagnetic field. It will produce the Metal oxide film which can inhibit the water rust producing.

Frequency conversion processing Application

Hard water treatment Advantages

| Concentration value | N=1.7 | N=4 |

| Water supply(m3/h) | 80 | 44 |

| Drain+wind loss(m3/h) | 47 | 11 |

If operation 8000hours per year, save water (80-44)c/h×8000h=28.8m3/year.

Frequency conversion processing Work principle

The video of working principle:https://www.youtube.com/watch?v=2NCjU1QT8kw

DESCALER creates a frequency-modulated electromagnetic field inside the supply pipe. This field forces the dissolved calcium (magnesium) and bicarbonate ions to create the crystallizing nuclei of calcium (magnesium) carbonate in the bulk of the water. These microcrystals continuously grow (the snowball effect) and they flow with the water in the form of suspended particles. Their size and shape is much different to those formed in untreated water, they don`t stick at the piping walls, heating elements of boilers or washing machines and they remain in suspension until discharged to drain.

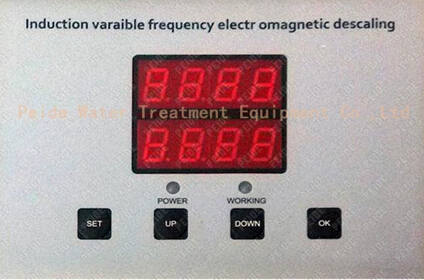

Frequency conversion processing Control way

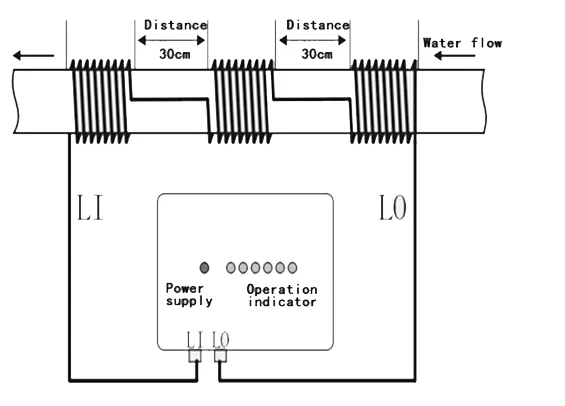

A completed unit consists of a control box, signal wire.

control box create electromagnetic field. Signal wire wound around pipes. Connect with power supply, electromagnetic signal transfer deliveries to wire. Wire transfer electromagnetic to water.

Dimension : https://www.youtube.com/watch?v=H9gMqXKWlKk

Main parameters include:

| Material: | Metal Shell (Main board) |

| Power input: | 20VAC 50HZ |

| Ambient limitation: | -10……+60°C |

| Ambient relative humidity: | ≤80% |

| Pipe External temperature: | common cable wire <70℃ |

| high-temperature allowance cable: | <130℃ |

| Pipeline diameter: | OD15mm to1500mm |

Frequency conversion processing Specification

| Model | Pipe diameter(mm) | Power (W) | Input Voltage |

| CLDC-2.5CR | 65 | 2.5 | 220VAC 50 HZ |

| CLDC-3CR | 80 | 2.5 | |

| CLDC-4CR | 100 | 3.0 | |

| CLDC-5CR | 125 | 3.5 | |

| CLDC-6CR | 150 | 5.0 | |

| CLDC-8CR | 200 | 13 | |

| CLDC-10CR | 250 | 18 | |

| CLDC-12CR | 300 | 26 | |

| CLDC-14CR | 350 | 28 | |

| CLDC-16CR | 400 | 33 | |

| CLDC-18CR | 450 | 38 | |

| CLDC-20CR | 500 | 42 |

Frequency conversion processing Installation